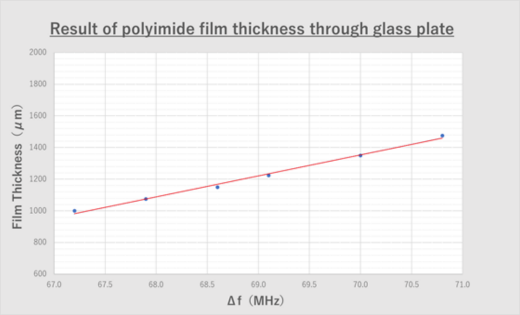

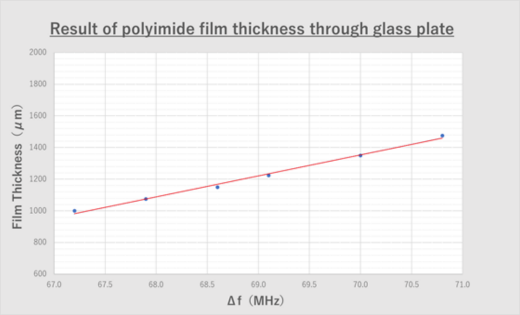

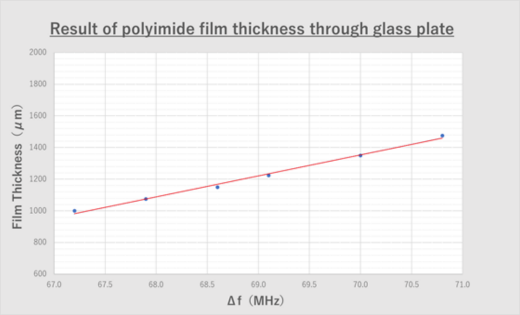

The curling probe can measure the film thickness of deposit (film-like deposit) attached to the tipof the probe.In fact, it is possible to measure the film thickness of organic film or CVD deposited film depositedon the glass.It can be used to check the device management and cleaning frequency. |

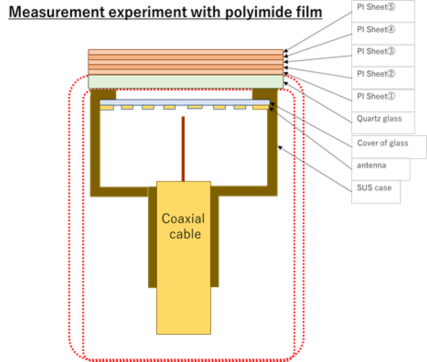

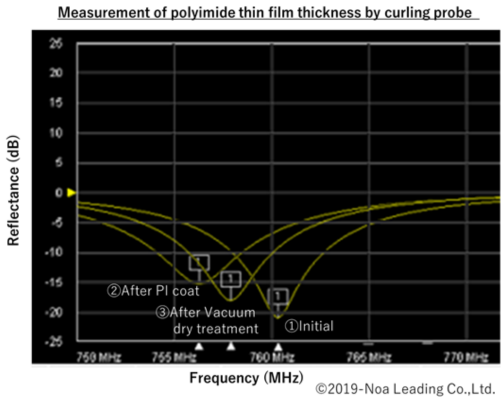

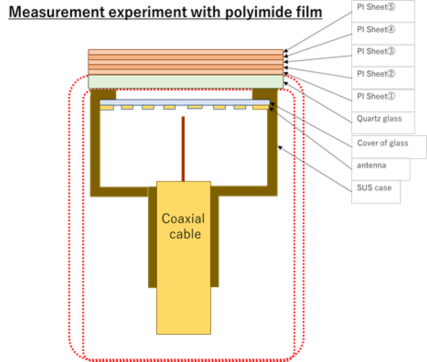

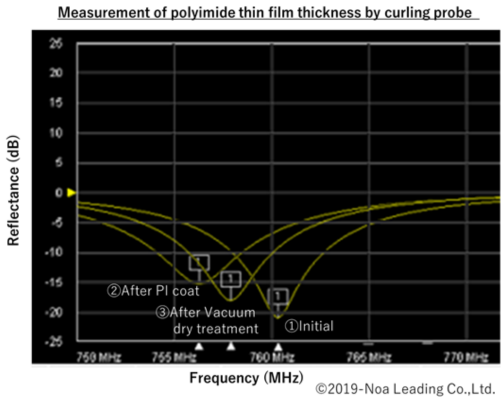

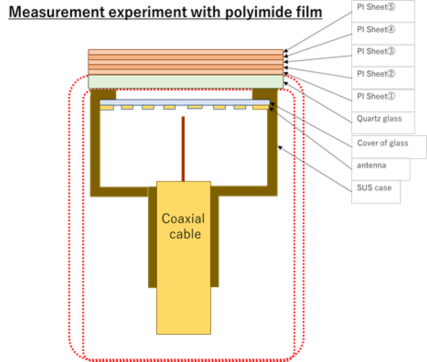

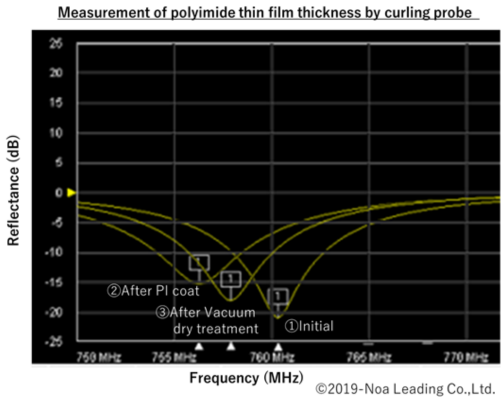

The following shows an example of measuring a thin polyimide film attached to the front glass of acurling probe as an application of the above measurement method.This measurement was made by examining the change in resonance frequency when a polyimidesolution was sprayed on the front surface of the glass of the curling probe and then dried in avacuum dryer.① is the initial absorption frequency. When the polyimide solution is spray-coated on the curlingprobe, a thin film of polyimide solution is formed on the front glass surface of the curling probe,and the resonance frequency shown in ② is obtained.After that, when the solvent of the polyimide solution is vaporized and evaporated with a vacuumdryer, the polyimide solvent film contracts and the resonance frequency increases, which can bemeasured as shown in ③.In this experiment, spray coating was performed, but in actual manufacturing equipment, the filmthickness of the deposit on the side wall can be measured by installing a curling probe on the sidewall in the chamber.This principle enables deposit management in the chamber. Expected to be applied to dustmanagement and foreign matter management in the chamber. |

|